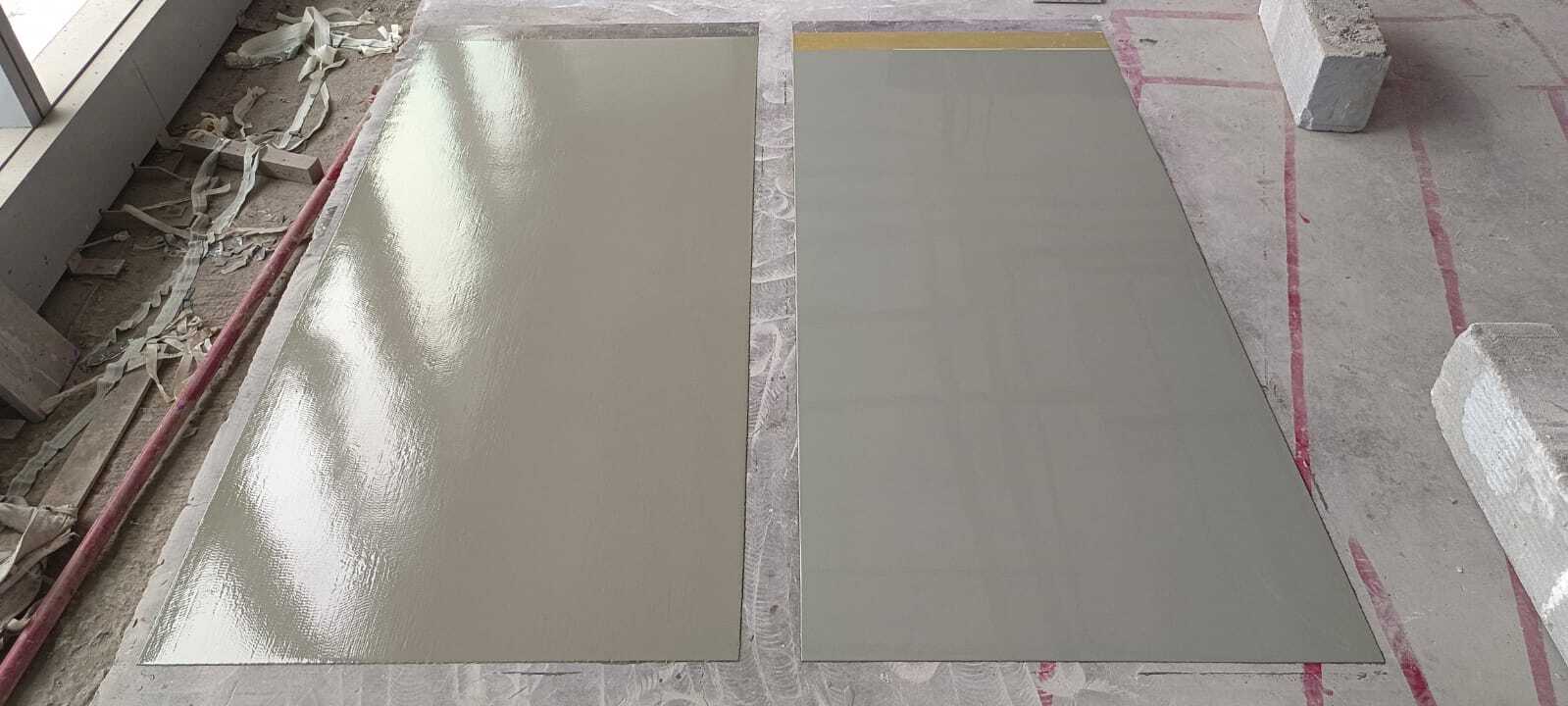

Epoxy Coating or Dustproof Coating

Product Details:

Epoxy Coating or Dustproof Coating Price And Quantity

- 100 , , Square Meter

- 400.00 INR/Square Meter

Epoxy Coating or Dustproof Coating Trade Information

- 20000 , , Square Meter Per Month

- Week

- Yes

- Free samples are available

- Central India, West India, North India, East India, Gujarat

Product Description

We are a leading company specializing in the business of offering our clients VariousEpoxy Flooring service. We provide following Epoxy Flooring Services:

Epoxy Flooring for Factories which includes 2-3mm Epoxy Flooring thickness

Epoxy Flooring for Data Center Projects. This includes ESD Epoxy Flooring system also. Average thickness used in Data Center is 3mm

Epoxy Coatings for Office areas (Used mainly below the Raised Access Floor System for Dustproofing). Coating thickness varies from 300 Microns to 600 Microns

Epoxy and PU Coating for Multilevel Car Park Flooring. Used for Car park areas of residential and commercial buildings. System thickness varies from 1.2mm to 2mm

Excellent Adhesion for Lasting Performance

Designed for industrial environments, this epoxy coating integrates a high-performance formulation for outstanding adhesion to concrete and metal surfaces. Whether applied in workshops, warehouses, or manufacturing units, the coatings robust bond ensures lasting durability and efficient dust-proofing. Its glossy finish not only enhances surface aesthetics but also supports easy cleaning and maintenance.

Effortless Application & Fast Drying

Applying this coating is straightforwarduse rollers, brushes, or sprayers to achieve uniform coverage. With a 45-minute pot life at 30C and a drying period of 6-8 hours, you can efficiently complete floor coating projects, minimizing downtime in commercial and industrial spaces. The products user-friendly formulation is tailored to meet the needs of distributors, suppliers, exporters, and service providers across India.

FAQs of Epoxy Coating or Dustproof Coating:

Q: How is the epoxy or dustproof coating applied for best results?

A: For optimal performance, the coating should be applied using a roller, brush, or spray after mixing the base and hardener in a 4:1 ratio by weight. Ensure clean surfaces before application, and work within the 45-minute pot life to prevent premature curing.Q: What is the recommended coverage area for two coats of this product?

A: Each 20-liter pack covers approximately 300-350 square feet with two coats, based on the recommended thickness of 100-120 microns per coat.Q: When should the coated floor be ready for use after application?

A: The surface typically dries within 6-8 hours after application. Its advisable to avoid foot or equipment traffic until curing is complete to maintain the glossy finish and strength.Q: Where can this industrial-grade epoxy coating be used effectively?

A: This coating is designed for industrial surfaces such as factory floors, warehouses, and workshops where dust-proofing and chemical resistance are required. Its excellent adhesion makes it suitable for both concrete and metal substrates.Q: What process should be followed to mix and apply the coating?

A: Combine the base and hardener in a precise 4:1 ratio by weight, mix thoroughly, and apply immediately. Ensure the mixed product is used within its 45-minute pot life at 30C for best results.Q: How does the coating offer benefits against chemicals and dust?

A: Formulated with effective chemical resistance, the coating protects floors from exposure to oils, solvents, and mild acids, while its dustproofing capability maintains a cleaner and safer work environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Get a Quote

Get a Quote

Send Inquiry

Send Inquiry Send SMS

Send SMS